Home > Production > Soft Tooling

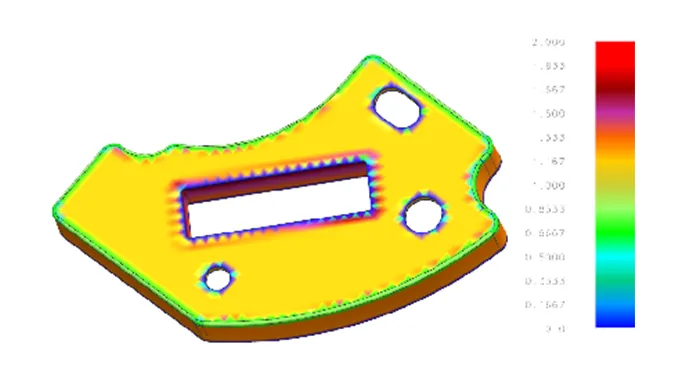

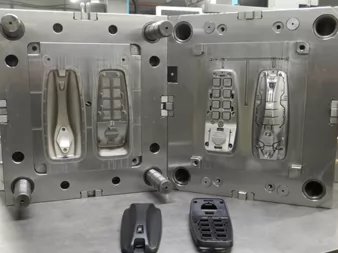

Soft Tooling & Injection Molding

At XC Precision, we use soft steel materials (such as P20) to make rapid molds, the cost is low and the processing speed is fast than the standard production mold.This is very common and the good choice for the prototypes or pre-production stage.

Advantages of Soft Tooling

● 7~14 working days to complete

● One mold with multiple cavities, reducing the pre-development cost

● Use injection-grade raw materials

● Slider and hot runners can be designed to achieve complex shapes and structures

● Produce high-quality plastic parts

● Made of steel, it can reach 50,000 shots, which is longer than aluminum molds.

Work Shop and Production Process View

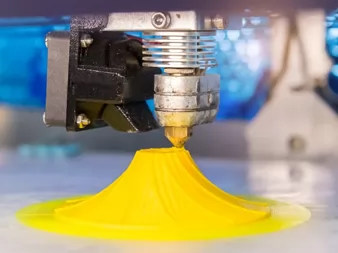

3D Printing

CNC Machining

Soft Tooling

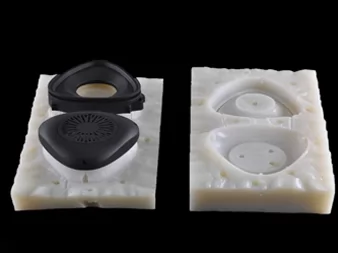

Vacuum Casting

Bending

Laser Cutting

NCT

NCT

Punching

Riveting

Tapping

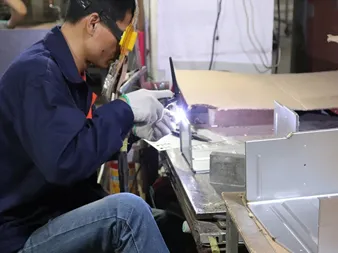

Welding

Various Surface Treatment Provided in XC Precision

Surface finishing is widely needed in our products from prototypes and production.

To improve the corrosion resistance and wear resistance of the product by changing the mechanical, physical and chemical properties of the surface layer.Or to get a good looking in the parts. We all need to do with the surface treatment in the original parts. Traditional surface finishing methods mainly include: Anodizing, Chromate, Galvanizing, Electrophoresis, Bluing, Blackening, Passivation, Spraying, Powder Coating, Polishing and Sandblasting.